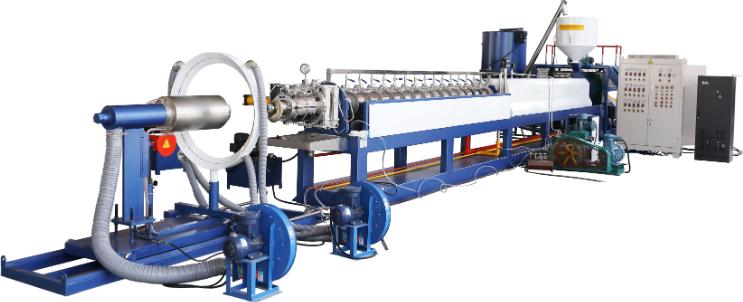

EPE Foam Sheet Extrusion Line

EPE foam sheet extrusion line production process instructions:

Mixing the polyethylene and other material----put mixed material to the hopper---through extruder heating and melting and the same time inject foam agent and monoglyceride at high pressure----extruded from machine head---shaping---cooling---hauling off---flatten---winding---finished products

EPE Foam Sheet Extrusion Line Main Parameters:

| Model | Screw Diameter (mm) | Products Width (mm) | Products Thickness mm | Total Power(KW) | Output Capacity kg/h | Foaming Ratio | Epe Foam Extruder Price |

| EFP-75 | 75 | 1600 | 0.2-3 | 55 | 25-50 | 9-64 | $29000.00~157,857.00 |

| EFP-90 | 90 | 1600~2000 | 0.2-5 | 75 | 60-90 | ||

| EFP-105 | 105 | 1600~2500 | 0.3-6.5 | 95 | 80-120 | ||

| EFP-120 | 120 | 1600~3000 | 0.5-8 | 115 | 120-180 | ||

| EFP-135 | 135 | 1600~3000 | 1-10 | 150 | 170-220 | ||

| EFP-150 | 150 | 1600~3000 | 2-12 | 220 | 250-300 | ||

| EFP-170 | 170 | 1600~3000 | 2-14 | 320 | 100-450 | ||

| EFP-180 | 180 | 1600~3000 | 3-16 | 330 | 300-500 | ||

| EFP-200 | 200 | 1600~3000 | 3-25 | 400 | 350-650 | ||

| EFP-220 | 220 | 1600~3000 | 3-27 | 450 | 400-700 | ||

| EFP-250 | 250 | 1600~3000 | 3-30 | 500 | 450-800 |

By subscribing to our mailing list you will always be updated with the latest news from us.

If you want to beat your competitors in product quality and capacity, you have to use our machine. The reasons are as the following:

1.Stability.

If you use our machine, you can work continuously for 30 days and nights without stopping it. Our customers had experience of working for 35 days and nights without stopping the machine.

2. The density of the EPE products

If you use our machine, you can get products with the lowest density of 14kg/m3 while some of our competitors make products with density of 20kg/m3. Assuming that you make 16kg/m3 products with our machine while your competitors make 20kg/m3 products. To make the same one ton of material, you can get 62.5m3 of products (1000kg ÷ 16kg/m3) while your competitor can get only 50m3 of products. (1000kg ÷ 20kg/m3). In this way, you can produce 12.5m3 more of products. That means you can get more profit of 12.5m3.

Of course, you can adjust the machine to make different densities of products. You can also make the same density products as your competitors if you want. However, your competitors can’t make as light products as yours with their machine. That is because the structure of our main machine parts are different from that of other machine manufacturers.

3. Low failure rate.

All the electrical parts of our machine are international famous brands. Their quality and performance are more reliable.

4. Easy operation.

Our machines have been tested by many customers and have been improved many times according to many customers’ feedback. The operation of our machine is more and more practical and easier and easier. We are the manufacturer in China that specially makes epe machine only and we are the leader of Chinese EPE foam machinery industry.

5. Professional service team.

We have engineers and technicians who engaged in the overseas installation and technical training. We also have conscientious salesperson and engineers who can give you the timely and best after-sale service.

In recent years many foreign customers bought EPE extruders to make sheets with thickness of 3cm, 5cm or 9cm. Because EPE foam has advantages of thermal insulation, moisture resistance, waterproof and collision prevention, especially because they are of low cost, people put these sheets on the floor to take the place of beds. They are very popular with customers in many developing countries such as India and African countries.