PE Foam Bag Sealing Machine

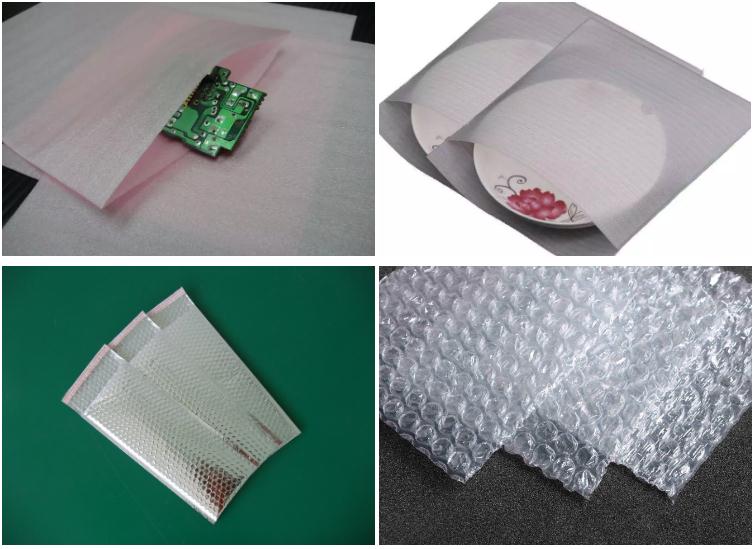

PE Foam bag automatic sealing machine is designed to seal PE foam sheet by electronic heaters to make elaborate PE foam bag through fully automatic process. Bag sizes are adjustable by feeding sheets` width

This PE foam bag automatic sealing machine is specially designed for making EPE bags.

There are two models for you to choose.

Single station bag making machine and double station bag making machine.

The daily output of double station bag making machine is higher.

Main Parameters Of PE Foam Bag Sealing Machine:

Model | Max. Width | Max. Length | Output(Bags/Min) | Total Power | Weight |

ZDJ-750 | 750mm | 800mm | 20-130 | 6.0kw | 660kg |

ZDJ-1000 | 1000mm | 850mm | 20-130 | 6.5kw | 750kg |

ZDJ-1250 | 1250mm | 1500mm | 20-130 | 7.0kw | 800kg |

ZDJ-1500 | 1500mm | 1500mm | 20-130 | 7.5kw | 850kg |

By subscribing to our mailing list you will always be updated with the latest news from us.

How to choose the right PE Foam Bag Sealing Machine?

First, you need to know about what material the products use. Is it PE, PP, PVC, PET or POF?

Secondly, you have to know the product thickness, width and length so that we can recommend the suitable machine according to those.

Thirdly, you have to learn about the way of sealing of the product. Is the sealing at the bottom? In the middle? Or on the side? Or is it 3-side sealing? For different ways of sealing, the machine models are also different.

You have to choose the model which suits the product width, it is impossible that the machine is multi-purpose. The wider the machine is, the more expensive the machine is.

There are high-speed machines, medium-speed machines and low-speed machines. You have to choose the suitable EPE bag-making machine speed according to your own requirement.

If the machine is pneumatic, you have to prepare air compressor. The model is according to the actual condition.

The size of the side-sealing bags and that of the bottom-sealing bags are opposite. The length of the side-sealing bags is the width of the bottom-sealing bags.

PE foam bag sealing machine advantages:

It adopts PLC control system which is easy to operate and the length of the bags is accurate.

It uses two-side water cooling system to make the bags. The cooling is fast, the hot cutting is neat and the sealing is strong.

It adopts automatic folding and feeding, it can cut the edges, and it can’t make the fault of bag misplacement. It can fully take the place of manual feeding so it can save a lot of labor cost.

It can make multiple bags at the same time, so the efficiency is raised a lot.

The hot cutting system is designed well, it suits thinner and softer bubble film and EPE sheets without blocking the machine.

If you adjust the parameter of the time, you can use it for making epe bags within 2mm thickness without adding more parts.

The sealing is strong.

Speed regulation is easy and stable.