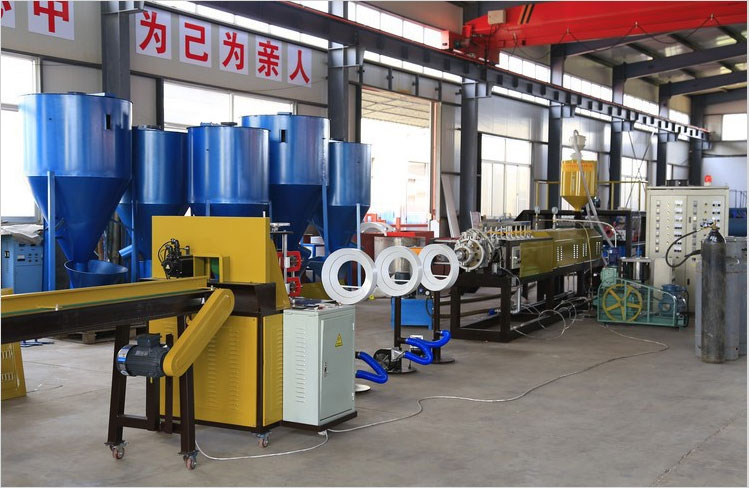

PE Foam Tube Extrusion Line

PE foam tube extrusion line produces qualified expanded cellular PE foam Tube&Rod by butane gas foaming method with several materials like GMS(Surface Active Agent), Talc, etc and providing the controlling system of each parts by automatic systems.

Main Parameters Of PE Foam Tube Extrusion Line:

Type | Unit | PEG-70 | PEG-75 | PEG-90 | PEG-105 | PEG-120 |

L/D |

| 55:1 | 55:1 | 55:1 | 55:1 | 55:1 |

Screw speed | r/min | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 |

Foaming rate |

| 20-40 | 20-40 | 20-40 | 20-40 | 20-40 |

Specification | mm | 20-40 | 20-50 | 30-80 | 40-100 | 50-120 |

Cooling method |

| Water cooling | ||||

Installed capacity | kw | 36 | 70 | 90 | 100 | 120 |

Dimension | m | 15×1.3×1.7 | 16×1.3×1.7 | 18×1.6×2 | 20×1.80×2 | 22×2×2 |

Total weight | t | 6 | 6.5 | 8 | 9 | 10 |

By subscribing to our mailing list you will always be updated with the latest news from us.

This EPE foam tube/rod extrusion line can produce EPE foam tube/pipe/rod/stick, which is a kind of new type foaming material and widely used as the air conditioner tube sheath, pool noodle, toy guardrail, etc due to its good foaming, elasticity and heat preservation character. Applications:

A. Applications Of Product

Non cross-linked closed cell polyethylene foam tube for plumbing, heating, refrigeration and air conditioning insulation

B. General properties

Polyethylene based product—inert material, highly resistant to chemicals

Environment friendly product: free of CFC, HCFC and chemical blowing agents

100% recyclable

Flexible low weight material, easy to slip and install

Low thermal conductivity

Compatible with all sealing materials

Fine round closed-cell cellular structure assures : negligent absorption and water permeability

Excellent impact and compression resistance even for low thicknesses