EPE Foam Pipe Rod Extrusion Line

Main Parameters Of EPE Foam Pipe Rod Extrusion Line:

| Model | unit | EFP-75 | EFP-90 | EFP-105 |

| Dia. of screw | mm | 75 | 90 | 105 |

| Dia. of product | mm | 10-60(tube) 6-38 (rod) | 10-60(tube), 6-38(rod) | 10-60(tube), 6-38(rod) |

| Output | kg/h | 20-40 | 30-70 | 40-100 |

| Line speed | m/min | 0-50 | 0-80 | 0-50 |

| Power supply | 380v./50hz | 380v/50HZ | 380v/50HZ | |

| Rated power | kw | 40 | 75 | 94 |

| Weight | t | 2 | 8 | 9 |

By subscribing to our mailing list you will always be updated with the latest news from us.

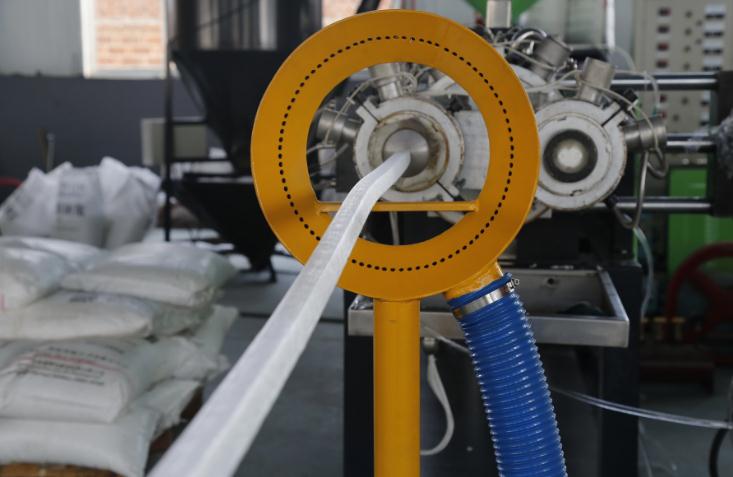

Main engine and screw part

Cooling and haulling and automatic cutting parts

Square tube extrusion screen

1. EPE Foam Pipe Rod Extrusion Line Products Description:

A: EPE foam sheet is a new type of soft packing material , also named as pearl cotton. It has the following advantages: damp proof, shockproof, sound insulation and high plasticity.

B: As a new type of packing material, EPE foam rod is widely used in furniture provention, air conditioner pipe cover, and other areas.

2. EPE Foam Pipe Rod Extrusion Line Features:

A: EPE foam rod production line adopts high speed hydraulic filter changer which has steady feature, can realize immediate change of the filter without stopping the machine.

B:EPE foam rod production line adopts PLC control system , touch screen operation, easily to operate.

C: width special single screw extruder, EPE foam rod production line has the features of effetive plasticizing , high extrusion speed and massive production.

3. EPE Foam Pipe Rod Extrusion Line Process:

plastic raw material-----mixing fillers-----heating extrusion-----foam agent injection----mixing plasticization----extrusion----cooling and foaming ----calibration and cutting----cooling and traction---spreading----winding----final products